The Gist

I will explain the reasons for these choices, but let me start out with where this is headed: I recommend covering the floor with sheets of luan, allowing nothing but friction and gravity to hold them all in place, and covering the seams with cheap, wide masking tape. At strike, pull the floor up and stack the sheets backstage. Put them back down for the next show and paint them again.

When your space is not just for theatre

When your theatre space is only for theatre, you have a lot of control over it. Some theatres casually paint their walls, move audience chairs around, and modify almost anything they wish in the space. However, a huge number of people are producing in spaces that serve other functions as well. A stage is sometimes more than just a place to put on shows. Some stages have finished wood floors that were a significant investment for a given school or college. Maybe the space is used for ceremonies, commencements, speeches, forums, or rallies. Maybe the space was funded by a wealthy benefactor and the hardwood floor was a considerable part of the cost. When the director or technical director asks the administration “Can we please paint the floor?” the answer might be a hard “no.”

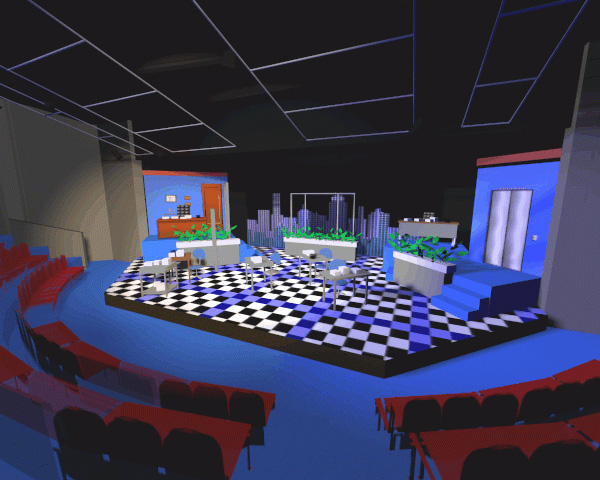

This is frustrating for the theatre people. In the space like the one shown here, the deck is a dominant element in the visual composition. Painting it would be cost-effective and would do a lot towards creating scenery for a show. A lot of people end up in this situation, and one thing they look for is a way to cover the floor and make it paintable.

Dance floors and marley and similar products are not what we are after here. We need freedom to paint anything we want. We need something paintable and durable. We’re going to compare the pros and cons of hardboard (some of you might use the commercial brand-name “Masonite”) and luan (sometimes spelled “lauan”).

Both of these come in sheets that vary in size depending on where in the world you are. In the United States, they are usually 4’x8′. They tend to be ¼” thick, and sometimes ⅛” (3mm to 6mm).

We want to cover the stage with one of these products. We need to know that they will not shift around. Of course, we have a bonus problem: If we cannot paint the floor, it is almost a given that we also cannot nail or screw or staple into it.

Our criteria for our floor are:

- The floor needs to be paintable.

- It needs to be cost-effective.

- It should be easy to install

- It should be reusable.

- It cannot be fastened down.

- Seams in the floor should be nearly invisible.

Materials to Consider

Hardboard is a dense, engineered sheet-good made of compressed wood fibers. It has no grain. A commonly used version is tempered hardboard, meaning it is more dense and is water-resistant. It is very smooth. It is fairly bendy, and it is heavy. Many theatres (including my own) use it as the top-layer of the deck. They screw it down, paint it semi-gloss black, and replace it maybe every three-to-five years. This might make it seem like the best choice, but it’s got some drawbacks for our temporary paintable floor.

The heaviness is a real problem. The corners crumble easily when bumped. Hardboard is great when you put it down and leave it alone, but if you strike this floor and put it back down each semester, these panels degrade very quickly, The biggest problem with hardboard is that all types of tape have trouble clinging to it. Paint can chip off of it easily too.

Luan is a type of plywood made from tropical lumber. It looks quite a bit like birch or maple. It has a visible wood grain, but usually has no knots. It is light-weight, easy to paint, and is fairly easy to carry. You can use very ordinary inexpensive paint. Tape clings to it well. One drawback as I write this is that it costs 15% to 25% more than hardboard. It is still a very inexpensive plywood.

Blue painter’s tape is engineered to be temporary and to let go easily. It is a very poor choice for covering seams between panels.

Gaff tape is our friend. We love it. It is the go-to when we are in doubt because it so rarely lets us down. In this case, though, let’s give it the day off.

When gaff tape is painted and catches stage light, it has a distinct fabric texture compared to wood. It’s better on muslin-covered flats. It is an expensive solution to a simple problem. These panels on the floor do not need any help staying in place. They just don’t. We do not need gaff tapes’ strength here. Cost and cosmetics rule it out.

Most of us don’t use classic inexpensive masking tape much in the theatre. It’s not as good as painter’s tape for masking. If someone uses it as spike tape it can ruin the floor. It’s nowhere near as strong as gaff tape. But for this application, it is ideal. I recommend at least two-inch wide tape for this. When painted, it is almost impossible to see on luan. It seals the seams thoroughly, so you don’t have to worry about paint leaking through to the floor. Best of all, it is really inexpensive. Use it liberally.

Installing the Luan Panels

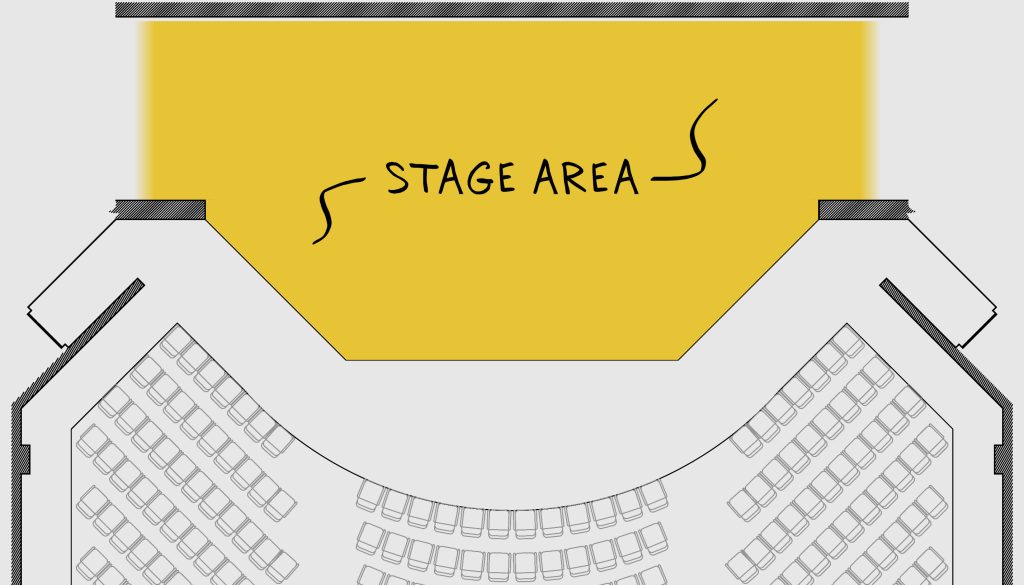

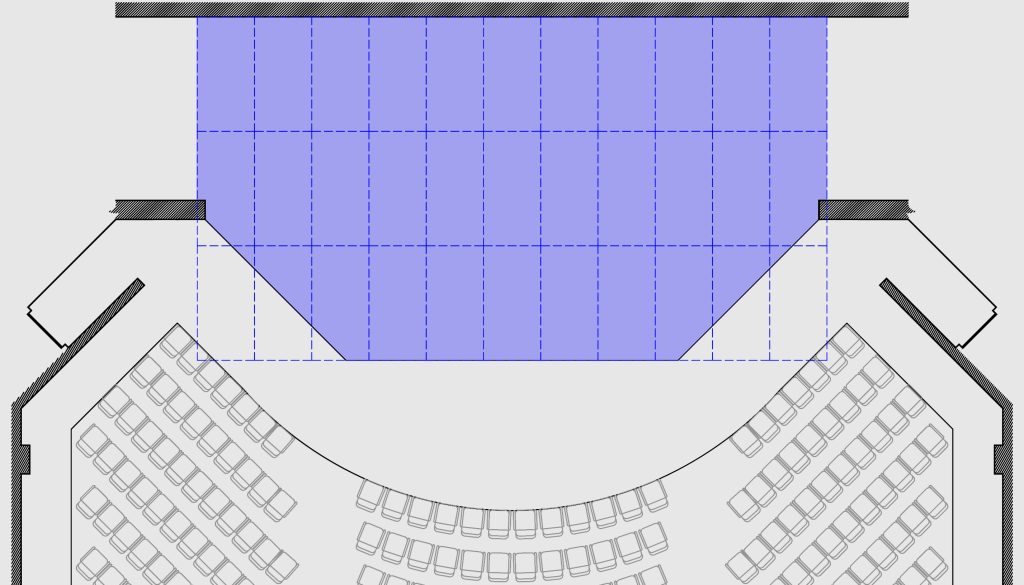

Most stages have a strange shape downstage. Figure out how deep you need to go into the wings, and whether or not you need to go all the way to the back wall. If you generally have walls or platforms midstage, you might not need to cover even half of your stage. If you have these panels stored and are reusing them every show, just put down as many as you need for a given set design.

I you have a curved apron, extend the luan over the edge and trace the curve out. A hand-held jigsaw will do a great job. Once you have the apron pieces cut, keep them in order when you store the floor so you do not have to cut them out again.

This design for How to Succeed in Business Without Really Trying was built in the space in we are discussing in 1998. I don’t have photos from the show, but this rendering shows you our floor. We covered the deck with luan panels, taped the seams with wide masking tape, and then painted.

Will the paint cause bowing and buckling?

I recall being asked once about buckling and bowing. When a sheet of luan is brand new and gets its first coat of paint, it can bow a little. When the luan is flat on the floor, this bowing is not enought to pull the luan away from its edges, and it passes in maybe an hour if it happens at all. I have never found it to be of any consequence. If I had doubts based on humidity or temperature, I might test a panel before installation to see if we might wish to do a simple primer coat. I would not even be worried about getting all the way to the edges if I were priming.

Storing the Luan Panels

I used this same simple floor technique for a summer children’s theatre company that produced annually in a high school theatre in New Hampshire. Ten different designs were built over ten years. We stored the luan with a lot of other stock in rental storage unit a good thirty minutes from the theatre. We stored them on edge, leaning against a wall in a thick stack. We often stored other things on top of them.

We added a few sheets of luan maybe every other year, but each piece would typically have a good six or eight shows painted on it before it was retired. We usually did not throw them out; we recycled them into other scenery instead.

We never stapled or screwed any of these to the floor, and we never had any incident of a panel sliding or shifting. Once they are all on the floor and surrounded by each other, they go nowhere.

Put the floor down first: Unexpected Benefit

Get the floor down as soon as possible, before any other scenic work begins. Get the tape applied. You now have a large area where you can paint almost anything you want. Props, furniture, etc. can all be carried to the middle of the stage. You obviously need to avoid messy spraying and spattering that goes into the wings, but your workspace is suddenly bigger and easier to manage as soon as you have the floor down.